Analysis of the cost-effectiveness of carbon steel strike anchors: comparison with stainless steel and galvanized anchors

2025-04-06

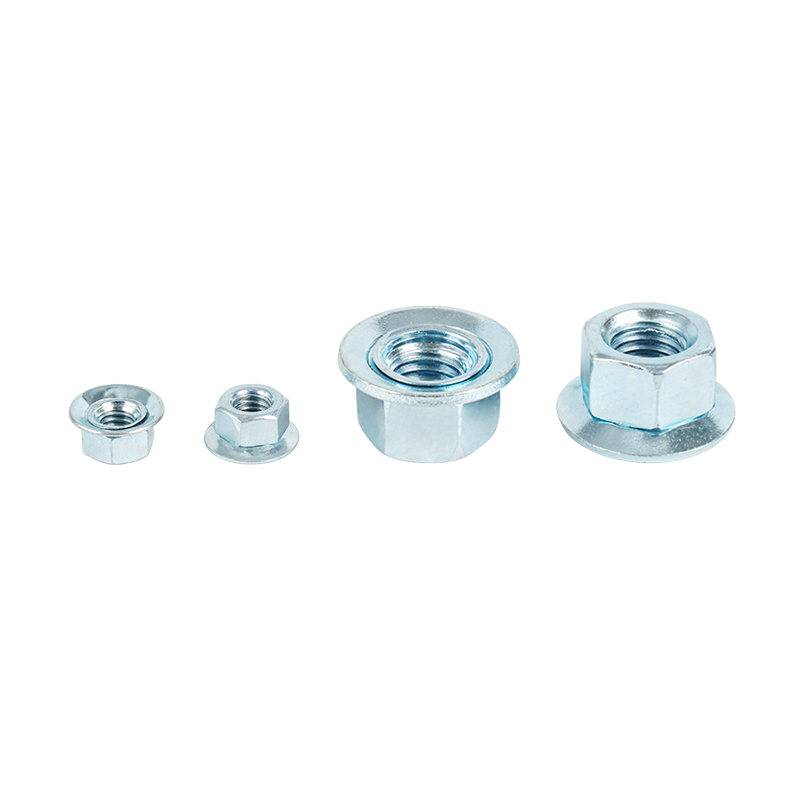

In the field of construction engineering and mechanical fixing, anchors are key connection components, and their material selection directly affects the safety, durability and economy of the project. Carbon steel strike anchors, stainless steel anchors and galvanized anchors are the mainstream choices in the market, but the cost-effectiveness differences among the three often cause controversy.

1. Material performance comparison: balance between strength and corrosion resistance

Carbon steel strike anchors

Tensile strength: The yield strength of carbon steel materials (such as Q235 or ASTM A307) is usually 235-400MPa, which can meet the needs of most high-load scenarios.

Corrosion resistance: Carbon steel itself is easy to oxidize, but through surface coating (such as phosphating, Dacromet treatment) or use with sealants, the rust resistance can be significantly improved.

Applicability: Suitable for short-term exposure or dry environments, such as indoor structures and temporary projects in non-coastal areas.

Stainless steel anchor bolts (such as 304/316)

Corrosion resistance: Stainless steel has excellent performance in humid, salt spray or chemical corrosion environments due to the passivation film formed by chromium elements, and its service life can reach decades.

Strength shortcoming: Although the tensile strength of stainless steel (304 is about 520MPa) is higher than that of ordinary carbon steel, its toughness is low and it is easy to break under impact load.

Galvanized anchor bolts

Protection mechanism: The hot-dip galvanized layer (average thickness 50-80μm) protects the substrate through sacrificial anodes and is suitable for moderately corrosive environments.

Limitations: The coating is easily detached due to mechanical impact or long-term wear, resulting in local rust diffusion.

Conclusion: Carbon steel anchor bolts strike a balance between strength and cost, stainless steel has outstanding corrosion resistance but is expensive, and the cost-effectiveness of galvanized anchor bolts is limited by the durability of the coating.

II. Cost-benefit analysis: Consideration of the cost of the entire life cycle

Initial purchase cost

The price of carbon steel impact anchor bolts is about 1/3-1/2 of that of stainless steel, which is 15%-20% lower than that of galvanized anchor bolts.

Take the M12×100 specification as an example (reference price in the Chinese market):

Carbon steel anchor bolt: 2.5-3.5 yuan/piece

Galvanized anchor bolt: 3.0-4.0 yuan/piece

Stainless steel anchor bolt: 8.0-12.0 yuan/piece

Maintenance and replacement costs

In non-extreme environments, carbon steel anchor bolts can be maintained for 5-8 years with protective treatment; if the environment is harsh, the anti-rust coating needs to be checked regularly.

Although stainless steel anchor bolts are maintenance-free, if they fail due to insufficient strength, the replacement cost may be higher.

Full life cycle economy

Short-term projects (<5 years): Carbon steel anchor bolts have the lowest comprehensive cost.

Long-term projects (>15 years): Stainless steel anchor bolts are better, but the initial investment needs to be weighed.

Galvanized anchor bolts are between the two, but the coating life is easily affected by the construction quality.

III. Application scenario adaptability

Scenarios where carbon steel impact anchor bolts are recommended

Dry indoor environment (such as steel structure workshops, equipment base fixation).

Short-term projects or budget-sensitive projects (such as temporary stages and exhibition halls).

High-load dynamic structures (need to take advantage of the high toughness of carbon steel).

Scenarios where stainless steel anchor bolts cannot be replaced

Highly corrosive environments such as coastal areas, chemical plants, and sewage treatment facilities.

Food and pharmaceutical industries (need to meet hygiene standards).

Compromise choice of galvanized anchor bolts

Moderately humid environments (such as ordinary underground garages).

Projects that are cost-sensitive but require certain rust prevention capabilities.

IV. Professional advice: How to achieve the best cost-effectiveness?

Accurately evaluate the environmental corrosion level

Refer to the ISO 12944 standard for corrosive environment classification (C1-C5) and match anchor bolts with corresponding protection levels.

For example, in the C3 (urban atmosphere) environment, the cost of carbon steel + heavy anti-corrosion coating solution is lower than that of stainless steel.

Application of composite protection technology

Carbon steel strike anchor bolts with epoxy resin coating or cathodic protection can improve corrosion resistance and extend service life to more than 10 years.

Standardized procurement and quality control

Choose carbon steel anchor bolts that meet GB/T 3098.1 (China) or ASTM F1554 (International) standards to ensure stable mechanical properties.

The cost-effectiveness of carbon steel impact anchor bolts is mainly reflected in medium- and short-term projects and dry or controlled corrosion environments. Its high strength, low cost and flexible protection upgrade space make it the preferred choice in most scenarios.

English

English 日本語

日本語