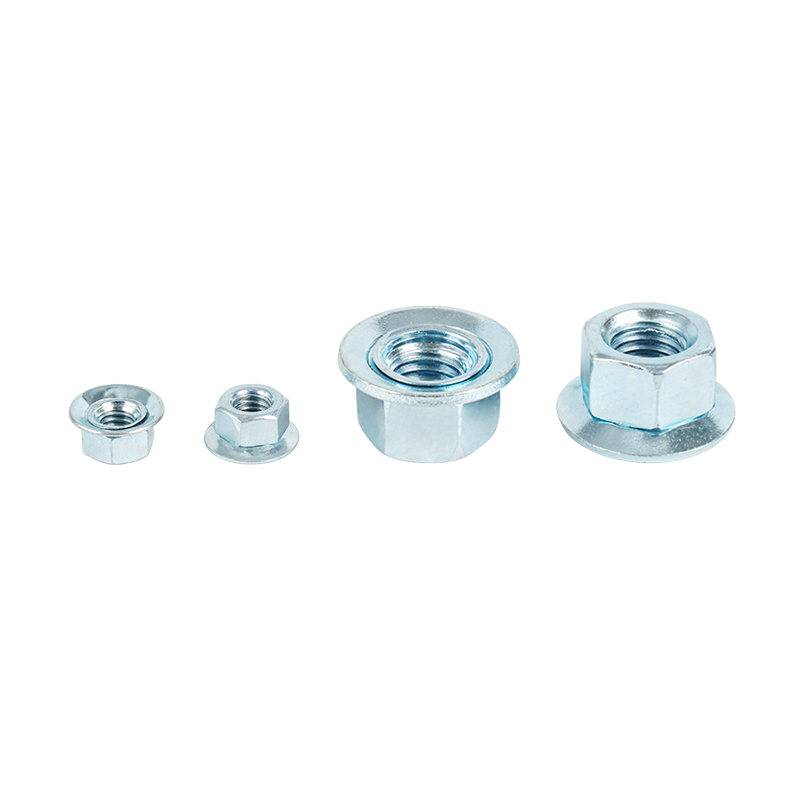

New Technologies Promote Fastener Manufacturing Upgrades

2024-09-29

The application of new technologies is driving upgrades in the fastener manufacturing industry. In recent years, advanced manufacturing technologies such as 3D printing, smart manufacturing, and the Industrial Internet of Things (IIoT) have become increasingly prevalent in fastener production. These new technologies not only enhance production efficiency but also improve product quality and consistency.

3D printing technology makes it possible to produce fasteners with complex structures while reducing material waste and production time. Smart manufacturing systems optimize production processes through automation and data analysis, achieving efficient resource allocation and precise quality control. Meanwhile, IIoT technology enhances transparency and control over the production process through device connectivity and real-time monitoring, improving the responsiveness and flexibility of the entire supply chain.

Additionally, advances in material science have fostered innovation in fastener products, leading to the development of lighter, stronger, and more corrosion-resistant materials. These new materials not only extend the lifespan of fasteners but also expand their range of applications.

Overall, the continuous emergence of new technologies is ushering the fastener manufacturing industry into a new era of greater intelligence, automation, and efficiency. Companies need to actively embrace these technological changes to maintain their competitive edge in the market.

English

English